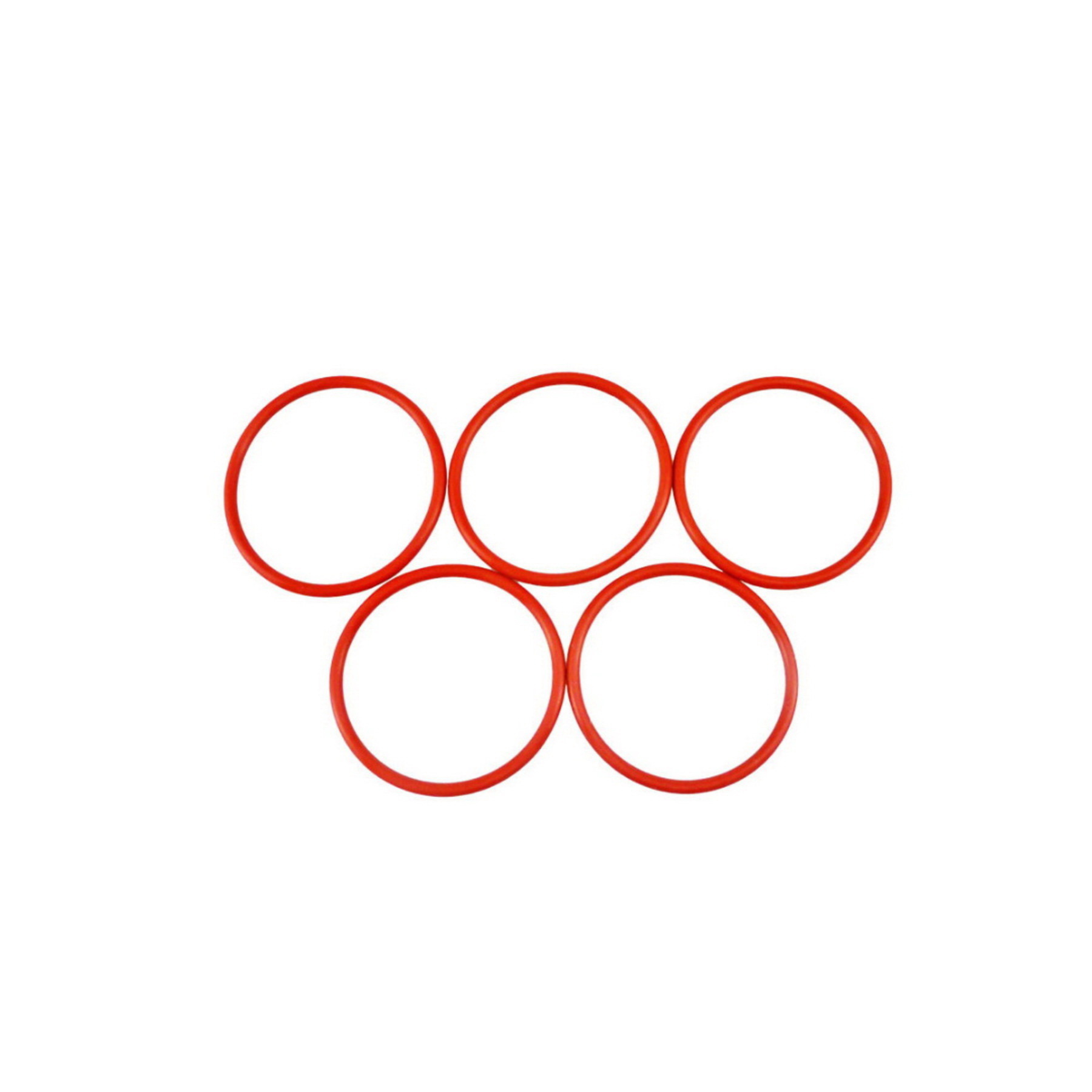

Various O-ringsUniversal for medical products

Product code: CT-1332

Product Category: O-ring O-ring

Product use: Widely used in various electronic product parts

The O-rings are normally for waterproof and oil resistance usage. The tiny o-ring can be made as small as 0.3mm dia.

O ring knowledgeINSERT MOLDING

The choice of O-ring materials is based on chemical compatibility, service temperature, sealing pressure, lubrication requirements, hardness, size and cost.

Synthetic rubber - thermoset polymer:

Butadiene rubber (BR), butyl rubber (IIR), chlorosulfonated polyethylene (CSM), EPDM, EPPR, fluoroelastomer (FKM), nitrile rubber (NBR) ), perfluoroelastomer (FFKM), acrylate rubber (ACM), neoprene (CR), polyisoprene rubber (IR), polysulfide rubber (PSR), tantalum rubber (SIR), styrene Ethylene rubber (SBR)

O-ring materials may fail due to high or low temperatures, chemical attack, vibration, wear and movement. Elastomers need to be selected under these conditions.

Some O-ring materials can withstand extreme temperatures as low as 73K or as high as 523K, but at the very low temperatures mentioned above, almost all engineering materials will harden and cannot seal, and at these extreme temperatures, the material may burn or decompose. . Chemical attack can decompose materials, cause brittle cracks in O-rings, or cause them to swell. For example, an unprotected nitrile rubber that is exposed to ozone gas may be damaged even at very low concentrations. If exposed to a low viscosity fluid, the O-ring may expand, causing an increase in size and a decrease in the tensile strength of the rubber. If an O-ring of the wrong size is used, it may cause a failure and the O-ring will not work properly.

Article Source:https://zh.wikipedia.org/wiki/O%E5%BD%A2%E7%92%B0